Position Determination Performance Analysis of P0-P4 Motor System Architecture

[car home New Energy] In the eyes of enthusiasts and technology controllers, the new energy vehicle is more like a work of art, and every core component is its essence. When talking about pure electric vehicles, they will ask you about battery manufacturers or battery suppliers, which can be regarded as the second brand of vehicles; When it comes to hybrid cars, they will ask you "P". What do these slang words mean? Today, I will talk to you about different types of motor architectures for hybrid vehicles.

At present, the application modes of motor architecture in the industry are different, and the specific applications and explanations under different architectures are also slightly different. The starting point of this paper is to sort out the basic principles and application modes of p0-p4 architecture and the purpose of different combination schemes.

● Definition and analysis of P0-P4 motor

In hybrid electric vehicles, it can be divided into P0-P4 and Ps architectures according to the different motor Positions, where P stands for motor position, and the motors in different positions play different roles, which are directly related to vehicle energy consumption and power performance. Which hybrid electric vehicle is more suitable for you?

◆P0 architecture: simple structure and early fame.

The motor with P0 structure is installed at the front end of the engine, which is connected with the crankshaft of the engine through a belt. The vehicle equipped with P0 motor can drive the mechanical compressor of the air conditioner to run when the engine stops at the traffic lights, so as to realize engine start and stop, braking energy recovery and power generation, and auxiliary power output.

"Bosch 48V MHEV System"

The technology and structure of P0 architecture are relatively simple and widely used. The automatic start-stop system that many drivers and friends shut down when they get on the bus is a typical P0 architecture, and the history of automatic start-stop can be traced back to 1970s. Compared with vehicles equipped with automatic start-stop function, P0 architecture adopts BSG (belt-driven starter/generator; Belt-driven starter/generator) motor, and equipped with a larger battery, can be competent to drive the compressor and auxiliary engine.

When the engine is stopped, P0 motor can drive the air conditioner compressor to work independently, thus reducing the idle time of the engine; When the vehicle starts or accelerates, P0 motor can assist the engine to run, help the engine quickly get rid of the inefficient working range, save fuel and effectively improve the driving quality. Because P0 motor transmits power to the wheels in series, the motor can’t drive the wheels independently without the engine, so there is no pure electric driving mode. In addition, the P0 motor is flexibly connected with the crankshaft through a belt, so the ceiling for applying force to the engine and recovering kinetic energy power is low.

"2020 modified Mazda CX-5 2.5L automatic four-wheel drive smart model"

Audi SQ7 TDI and Mazda i-Eloop belong to P0 architecture. Because P0 architecture has low transmission efficiency and the motor can’t directly drive the wheels, P0 motor usually appears as an auxiliary in the field of new energy vehicles. There will be corresponding analysis and cases in the following.

◆P1 architecture: independently developed/highly integrated.

P1-based motor is located at the rear end of the engine crankshaft, which replaces the traditional flywheel. Besides inheriting the function of flywheel to store energy and inertia outside the engine power stroke, P1-based motor has similar functions as P0-based motor, and also supports engine start and stop, braking energy recovery and power generation, and auxiliary power output.

Honda IMA hybrid system

Compared with P0 architecture, P1 architecture is more compact, and its motor is integrated in the engine housing. The design needs to consider the volume of the engine and the layout in the engine room. Because different gearboxes need corresponding design schemes, the research and development and manufacturing costs of P1 motor are relatively high. Existence is reasonable, and high investment often corresponds to high return. The engine crankshaft acts as the rotor of P1 motor, which has higher power transmission efficiency, better fuel saving effect and more obvious improvement on driving performance. In addition, P1 motor can apply auxiliary braking torque through electromagnetic field adjustment on downhill section to improve safety.

Although they are in different positions, P0 and P1 are connected with the same disease. As long as the motor rotates, the engine crankshaft must rotate, so the motor can’t drive the wheels alone, and there is no pure electric driving mode. In the kinetic energy recovery and sliding mode, the kinetic energy is wasted because the crankshaft must be driven to idle, and the noise and vibration are also increased because of the internal combustion engine following.

"Mercedes M254 Engine"

"2020 Mercedes-Benz E-Class (imported)"

A few days ago, the E350 model launched by Mercedes-Benz overseas adopted a 2.0T 4-cylinder engine code-named M254, and added 48V light mixing technology in the electrification transformation process. The ISG motor equipped with it has a maximum power of 12kW and a peak torque of 180N·m, which alleviates the performance of turbine lag when the wheels start and accelerate. This system is a typical P1 architecture. Officially, the motor is named "FAME" (modular engine). Some foreign media have speculated that this motor will appear on other PHEV models.

◆P2 architecture: modular design/strong fuel economy and wide application.

The P2-frame motor is located between the engine and the gearbox. Because it is not necessary to be integrated in the engine housing like P1 motor, the layout can be more flexible. The structure can be equipped with 1-2 clutches between the engine and the gearbox, which can be divided into three layout modes: ① Single-clutch structure in which the motor is arranged in front of the clutch, and the motor plays the role of assisting, parking power generation and starting the engine, which is similar to P1 structure; (2) Single-clutch structure in which the motor is arranged behind the clutch, so that the motor can drive the vehicle independently, recover braking energy, generate electricity and assist; ③ The motor is arranged in the middle of the dual clutch structure, so that the motor can drive the vehicle independently, and can also start the engine or park for power generation.

P2 architecture has strong compatibility and can be matched with all gearboxes (including manual gearboxes). P2 architecture is widely used in hybrid vehicles at present, and many parts suppliers have mature solutions. Take Borgwarner’s P2 motor module as an example. It integrates a dual-mass flywheel and an engine release clutch, which can disconnect the clutch and the motor direct-drive vehicle. It can convert an internal combustion engine-powered vehicle into a hybrid vehicle without changing the engine and gearbox, which means that car companies can expand the power combination of vehicles and enrich the product line of hybrid vehicles with less investment, shorter time and greater flexibility.

"Audi A3 e-tron Power System"

"2017 Audi A3 new energy (imported) Sportback e-tron comfort type"

Audi A3 e-tron is a representative model with P2 architecture. It is equipped with a 1.4T engine and a permanent magnet synchronous motor with a maximum power of 75kW. The battery capacity of the car is 8.8kWh, and the pure electric cruising range is 50km under NEDC condition.

◆P3 architecture: efficient power transmission and large space occupation.

The P3-frame motor is located at the output end of the gearbox, and its pure electric drive and kinetic energy recovery efficiency are high, and the effect of rapid acceleration is very direct. In terms of function, P3 motor can realize braking energy recovery and pure electric drive vehicles. Because the motor can’t be integrated with the gearbox or engine, it needs to occupy extra volume, so P3 architecture is more suitable for rear-wheel drive, and there is enough space for layout.

Compared with P0, P1 and P2 architectures, P3 architecture’s power transmission path does not pass through the gearbox, so the efficiency of pure electric drive and braking energy recovery is higher, and at the same time, the working time of the gearbox is reduced, which is helpful to prolong its service life. But the problem is also obvious, P3 motor can’t realize parking charging, and the shortcomings of outdoor camping and other use scenarios are exposed.

The representative model is BYD Qin PHEV, which is a parallel hybrid car with P3 motor as the core. With the original large-capacity battery setting, it not only meets China’s pure electric endurance of 50km for PHEV, but also can stack the performance of engine and motor to achieve stronger power output.

◆P4 architecture: realize four-wheel drive.

P4 frame motor and engine do not drive the same shaft, thus helping the vehicle to realize four-wheel drive. It can be a motor that drives the front axle/rear axle, or it can simply cancel the axle just like Acura NSX, and directly use two hub motors to drive the wheels. P4 architecture is similar to P3 in function, which can realize braking energy recovery and pure electric drive vehicles.

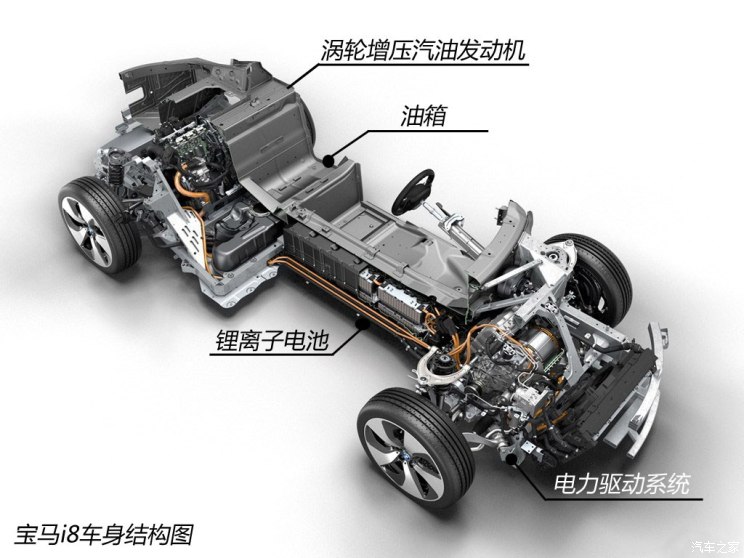

"2020 BMW i8 Extreme Night Meteor Limited Edition"

P4 architecture is mostly used in plug-in hybrid vehicles, and sports cars are more commonly used, such as porsche 918 Spyder, Acura NSX, BMW i8 and other sports cars. Take BMW i8 as an example. This 1.5T three-cylinder engine squeezes out the maximum power of 231Ps and the maximum torque of 320 N m. The maximum power of the permanent magnet synchronous motor on the front axle is 131Ps and the peak torque is 250 N m. It is equipped with a two-speed automatic gearbox to adjust the torque. The official acceleration time of 0-100km/h is 4.6s, which brings excellent power and can effectively reduce fuel consumption.

◆Ps architecture: parasites of double clutch

P3 motor is coupled at the output end of the gearbox, and Ps motor is directly integrated inside the gearbox. Because of the close location distribution, Ps architecture is easily confused as P3 architecture. Ps architecture is based on dual-clutch gearbox, which uses the characteristics of dual-clutch gearbox with two input shafts to integrate the motor on one of the shafts, and can realize pure electric drive vehicle and braking energy recovery.

"PS architecture power transmission mode"

The motor, clutch and reducer of Ps structure are put into the same shell, which is more fuel-efficient and smoother. But the disadvantages are also obvious, because the even shaft of the dual-clutch gearbox bears more torque than the odd shaft, which will lead to the inconsistency between the two shafts and the clutch wear; In addition, the integration of the motor into the gearbox will increase the maintenance cost, because it is the gearbox assembly that needs to be disassembled regardless of gearbox failure or motor failure.

"2021 Borui New Energy 1.5T ePro Leading Edition"

At present, among China brand car companies, Great Wall, Chery and Geely are all studying DHT gearbox, which is the cornerstone of Ps architecture. Taking Geely Automobile as an example, the 1.5T+7DCTH plug-in hybrid system of Geely ePro family models has the characteristics of high motor efficiency and high powertrain matching, and has the comprehensive advantages of high efficiency, excellent space and good quality (high cost performance). Among them, the efficiency of Ps frame motor is 97%, which is about 2% higher than that of P2 coaxial motor. The working speed of Ps frame motor is not limited by the engine, and the engine and motor can work in the high efficiency area at the same time, which can effectively reduce the fuel consumption of the whole vehicle.

●Combined frame motor

Brothers in battle, fathers and sons in battle, and motors with a single architecture all have shortcomings more or less, so combining two or more architectures of motors becomes the best solution at present. On P3 or P4 frame vehicles, it is necessary to install another motor for the engine in order to perform the engine start-stop and power generation functions, so many hybrid vehicles have two motors, forming a combined configuration of Px+Py. For example, WEY P8 has a BSG motor at the front end of the engine and a permanent magnet synchronous motor at the rear axle, which belongs to P0+P4 configuration. Let’s understand the technical characteristics of the combined structure motor through the development of domestic and foreign car companies and the analysis of car models.

◆ Volvo PHEV Technology Review and T8 Powertrain Analysis

In 2013, Volvo’s first-generation plug-in hybrid (PHEV) technology was applied to S60 PHEV models, adopting P0+P4 architecture, consisting of a BSG motor with 15kW engine front-end power and a 50kW permanent magnet synchronous motor with rear drive axle; In 2015, Volvo’s second-generation PHEV technology was applied to XC90 PHEV models, adopting P1+P4 architecture, consisting of an ISG motor with a power of 35kW and a permanent magnet synchronous motor with a rear drive axle of 60kW; At present, Volvo adopts the third generation PHEV technology based on CMA vehicle platform, and adopts a hybrid powertrain composed of an engine matching P2 motor.

As for the specific vehicle type, Volvo XC90 PHEV adopts a hybrid powertrain with P1+P4 architecture. The front axle of the vehicle is equipped with a gearbox integrated motor named C-ISG (Crank-integrated starter generator), which has three functions of start-stop control, power generation and assistance, and the rear axle is also equipped with a motor with the maximum power of 65kW. At present, Volvo’s PHEV models cover cars, station wagons and SUVs, all of which use modular PHEV powertrains.

◆ Evolution history of BYD DM system and analysis of the third generation DM system.

Since 2008, BYD’s DM system (Dual Mode system) has been upgraded twice. At present, the upgrade of the plug-in hybrid of the third generation DM is not only in terms of power, but also in terms of "performance" attributes of the whole BYD model after the "542" plan was put forward from the second generation DM system.

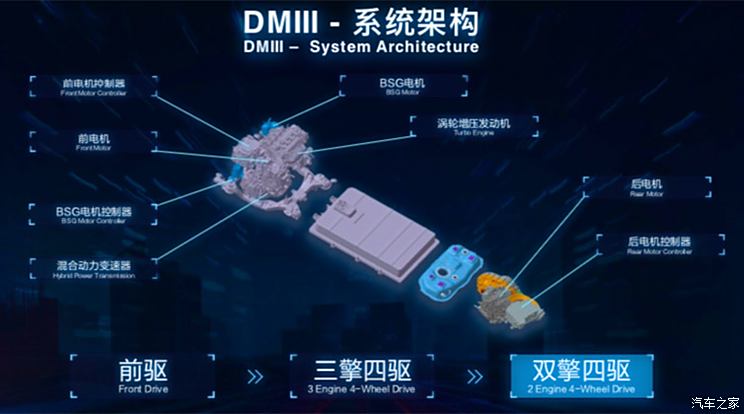

"High power consumption" is an obvious problem in the second-generation DM system. BYD thinks that BSG motor+electronic control system can solve the problem of "avoiding the inefficient area of the engine", assist the vehicle to generate electricity, make the whole energy flow system more balanced, and bring better acceleration performance, so the brand-new "BSG architecture" system is one of the core upgrades of this generation DM3.

The biggest purpose of BSG motor of the third generation DM system is not only to provide start-stop function servo for the engine, but also to charge the power battery while driving, and it can also be used to improve the acceleration performance. When the vehicle is driving in the all-electric drive mode, when the engine is involved, the BSG motor will drive the engine to start, so as to reduce the shock and assist in gear shifting.

Full text summary:

With the stricter emission standards and the support policies for new energy vehicles, OEMs pay more and more attention to the new energy market. Compared with the development of a brand-new hybrid system, the P2 technical route with modular design does not need to change the existing structure, is easy to integrate and is suitable for matching all gearboxes. Even if the fuel saving effect is not as good as that of parallel connection, the fuel consumption can be reduced at a lower cost, which has become a "shortcut" for many car companies. (Text/car home Zhang Wenhao)